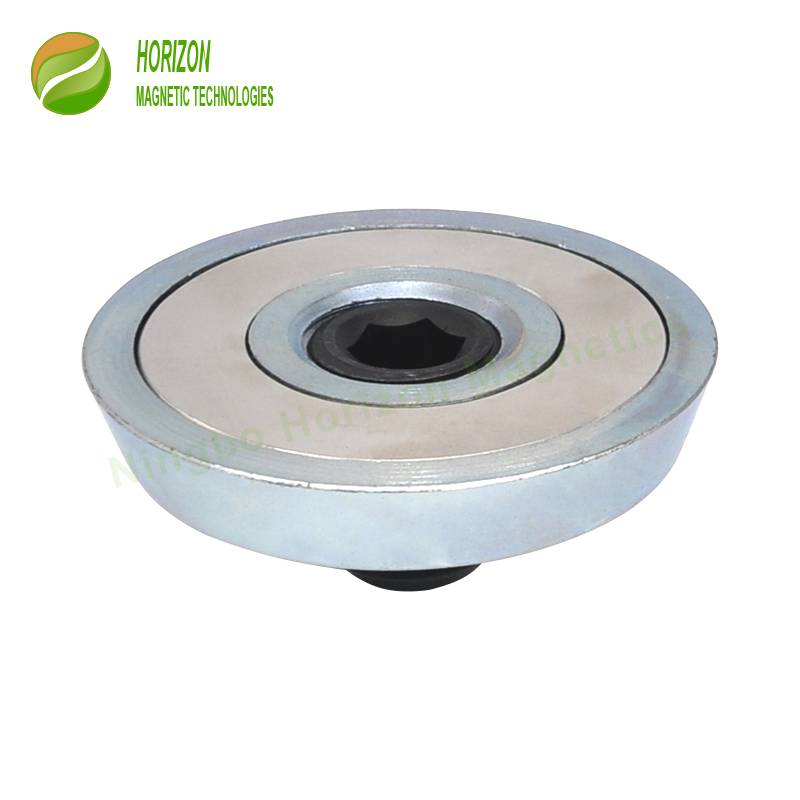

Feela joalo kaNeodymium pitsa ea makenete, makenete e kenyang e na le lesale la NdFeB makenete, casing ea tšepe le molamu oa khoele. Casing ea tšepe e sireletsa makenete ea Neodymium ho tsoa tšenyo ea kantle mme e tsepamisa matla a khoheli a koaetsoengNeodymium ring magnetsebakeng se hokahaneng feela ho hlahisa matla a phahameng haholo ho feta makenete a Neodymium a arohaneng. Leha ho le joalo e na le lintlha tse fapaneng ho tsoa ho makenete ea pitsa e le ho fihlela tlhoko ea kopo ka konkreite ea precast. Sebopeho sa casing ea tšepe se tebile 'me molamu oa khoele o ka feto-fetoha e le hore makenete e kentsoeng e be bonolo ho tloha konkreite e thata ka wrench ea socket.

1. Boitsebiso: Mokete oa Neodymium o nang le ts'ebetso e phahameng le kereiti + ea tšepe ea tšepe le molamu

2. Ho roala: Magnet e koahetsoeng ka NiCuNi kapa Zinc + casing ea tšepe e tlotsitsoeng ka Zinc kapa Koporo.

3. Boholo le matla: Ho bua ka Boitsebiso ba Teknoloji

4. Sephutheloana: E pakiloeng ka mabokose a masenke. Mabokose a kentsoeng phaleteng ea lepolanka kapa mokotlana oa bongata bo boholo

1. Matla a makenete le moralo o ikhethang le sebopeho li nolofalletsa khanya le ho sebetsa habonolo.

2. E ka sebelisoa hape ebile e tšoarella ho boloka litšenyehelo tse arolelanoang ka nako e telele.

3. E potlakile ho beha maemo le ho ntlafatsa katleho le litšenyehelo.

4. E ka ntlafatsa boleng ba likarolo tsa konkreite tsa precast.

5. Matla a Magnet a phahame ka ho lekaneng ho beha le ho tiisa likarolo tse kentsoeng ka nepo nakong ea ho lahla konkreite kapa ts'ebetso ea ho thothomela ho nolofalletsa ts'ebetso e sireletsehileng ea ho phahamisa.

1. Tsebo e ke keng ea hlōloa ho Neodymium magnet, karolo ea bohlokoa ka ho fetisisa ho netefatsa hore ho kenya boleng ba makenete.

2. Tsebo ea matla a khoheli le boqapi ba ka tlung e thusa bareki ho lemoha lihlahisoa tsa bareki ho tloha mohopolong ho isa lihlahisoa tsa ho qetela tsa makenete habonolo.

3. Mefuta e mengata le boholo bo teng ho boloka litšenyehelo tsa lisebelisoa le theko ea sehlahisoa bakeng sa bareki

4. Lisaese tse tloaelehileng tse fumanehang 'me li fumaneha bakeng sa ho tsamaisoa hang-hang

5. Phepelo e felletseng ea limakete tsa konkreite tse kentsoeng ho kenyelletsalimatlase tse koalang, li-chamfer tsa makenete le lihlahisoa tse entsoeng ka mokhoa o ikhethileng ho kopana le theko ea bareki hang-hang

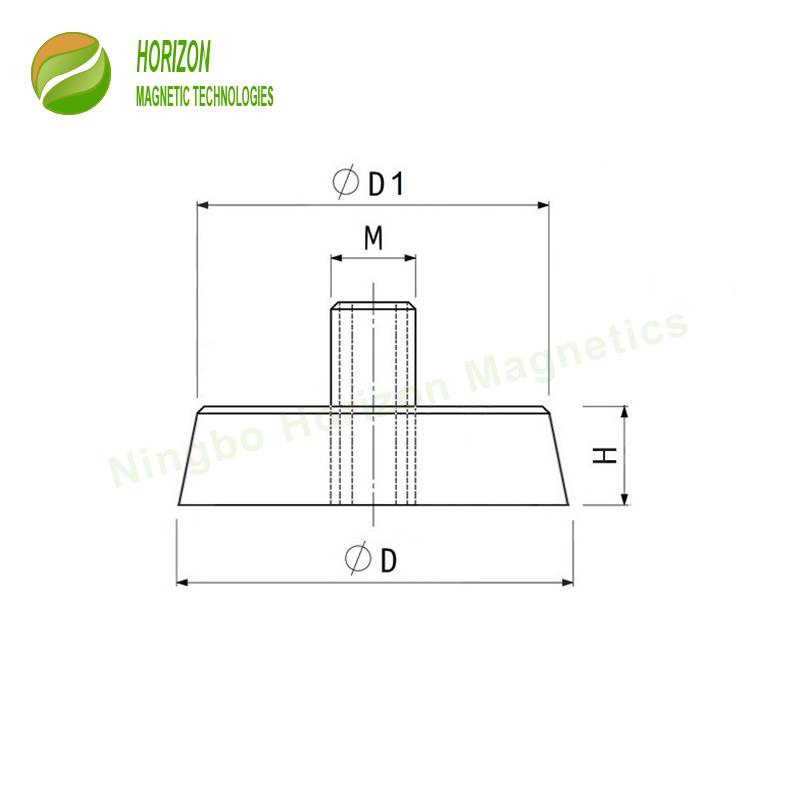

| Nomoro ea Karolo | D | D1 | H | M | Mocheso o Moholo oa ho sebetsa | |

| mm | mm | mm | mm | °C | °F | |

| HM-IN45-M8 | 45 | 40 | 8 | 8 | 80 | 176 |

| HM-IN45-M10 | 45 | 40 | 8 | 10 | 80 | 176 |

| HM-IN54-M12 | 54 | 48 | 10 | 12 | 80 | 176 |

| HM-IN54-M16 | 54 | 48 | 10 | 16 | 80 | 176 |

| HM-IN60-M20 | 60 | 54 | 10 | 20 | 80 | 176 |

| HM-IN77-M24 | 77 | 73 | 12 | 24 | 80 | 176 |

1. Qoba sekoaelo sa grout holim'a makenete e kentsoeng ea Neodymium ho boloka matla a khoheli.

2. Sebetsa kapa boloka makenete e kenyang ka tlase ho 80℃. Mocheso o phahameng o ka etsa hore makenete e fokotsehe kapa e lahleheloe ke matla a khoheli ka botlalo.

3. Ho khothaletsoa haholo hore liatlana li lokela ho apesoa ho sireletsa matsoho a basebetsi hore a se ke a phunya matla. Ka kopo e behelle hole le lisebelisoa tsa elektroniki le litšepe tse sa hlokahaleng tsa ferromagnetic. Tlhokomeliso e khethehileng e lokela ho sebelisoa haeba motho a roetse mochine o otlang pelo, hobane matla a khoheli a matla a ka senya lisebelisoa tsa elektroniki tse ka har'a li-pacemaker.