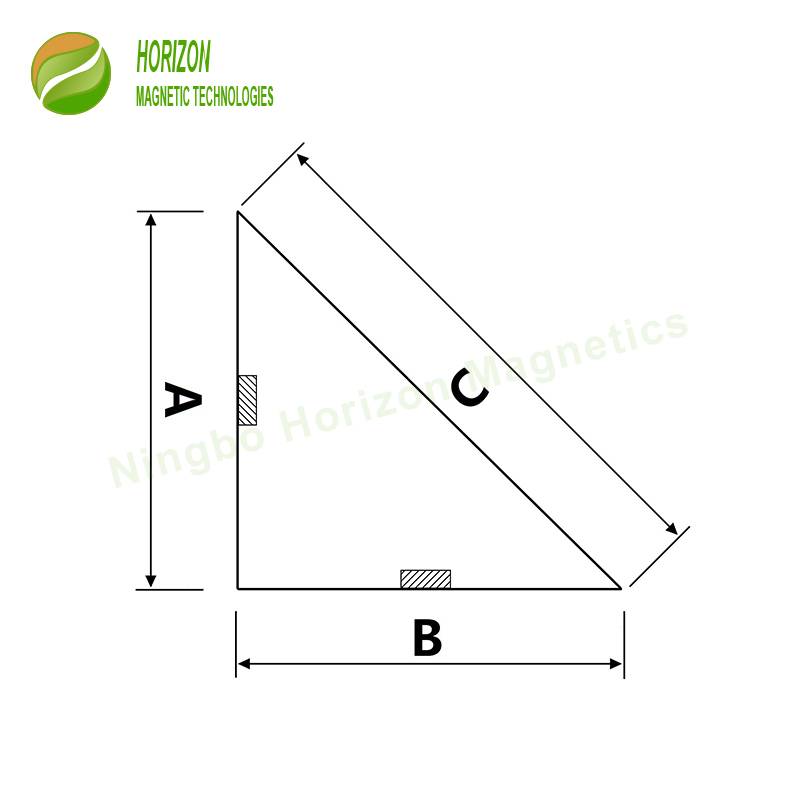

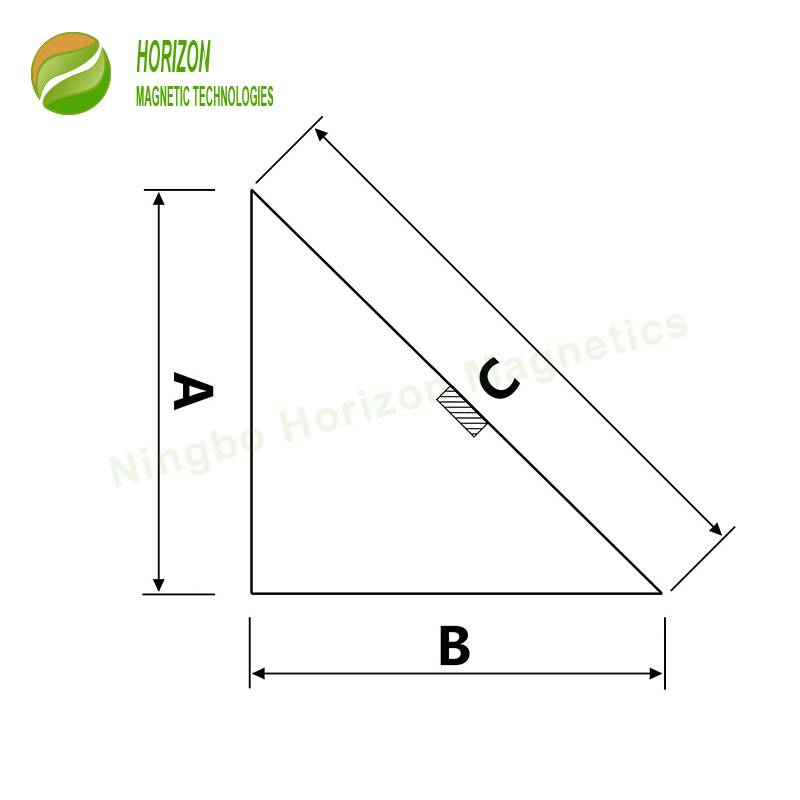

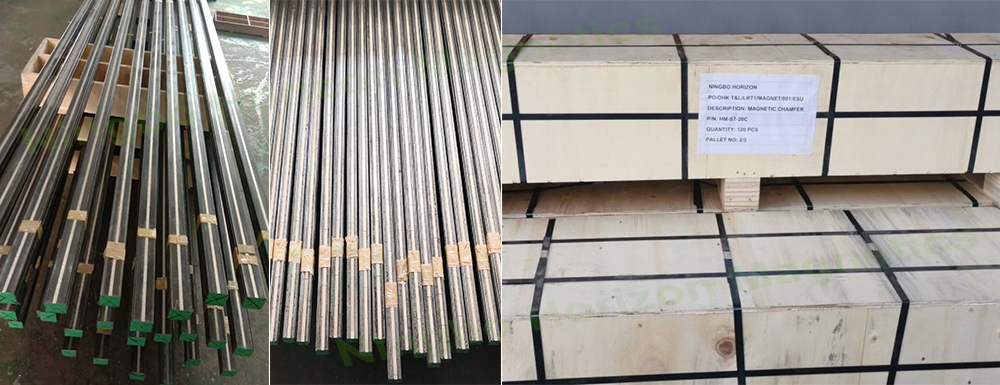

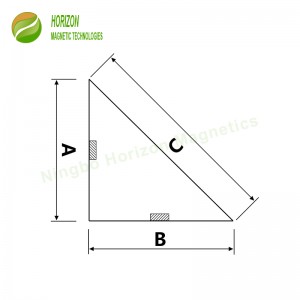

E entsoe ka matlaLimanete tsa Neodymium bare kentsoeng ka tšepe ea boleng bo holimo. Joalo ka sebopeho le molao-motheo oa limakete tsa kanane tsa Neodymium, tšepe e tsamaisa polarity ea limatlase tsa Neodymium ho tloha lehlakoreng le leng ho ea lehlakoreng le leng le amanang le matla a holimo. Ho feta moo, limakete tse ngata tse nyane tsa bar li sirelelitsoe ke tšepe ho tsoa tšenyo ea mochini. Lehlakore la ho ikopanya le etsa hore ho be le sebaka se potlakileng le se nepahetseng sa chamfer ea tšepe kahong ea tšepe ea tšepe ntle le ho thella kapa ho thella. Magnetic chamfer ke isosceles e kgutlotharo e nepahetseng mme e ka romelwa ka boholo bo fapaneng ka dimanete ka lehlakoreng le le leng, mahlakoreng a mabedi kapa hypotenuse ka bolelele bo felletseng ba 100% kapa ka 50% feela ya bolelele.

1. Ho bonolo ho sebetsa

2. E ka sebelisoa hape ebile e tšoarella ho fokotsa matsete a arolelanoang ka nako e telele

3. Ha ho li-screws, bolts, welding kapa motlakase o hlokahalang ho tiisa chamfer ea makenete. Ka potlako ho beha, tlosa le ho hloekisa

4. Universal e nang le mekhoa e mengata ea konkreite ea precast ho fokotsa theko ea bongata le litšenyehelo bakeng sa litsamaiso tse fapaneng

5. Matla a sekhomaretsi a matla haholo le bophelo bo bolelele ba ts'ebeletso ho feta chamfer ea rabara

6. Ho ntlafatsa sephetho sa boleng ho lihlahisoa tsa konkreite tsa precast ho felisa mathata a mangata a ho qeta mohaho

1. Matla a matla a tlholisano a matla a matla a khoheli le ts'ebeliso indastering ea konkreite ea precast mme o tseba seo le mokhoa oa ho netefatsa li-chamfers tsa tšepe,limatlase tse koalangle ho kenya makenete ho rarolla mathata a bareki

2. Lisaese tse ngata li fumaneha ho boloka litšenyehelo tsa lisebelisoa ebe theko ea sehlahisoa bakeng sa bareki

3. Lisaese tse tloaelehileng tse fumanehang 'me li fumaneha bakeng sa ho tsamaisoa hang-hang

4. Litharollo tse entsoeng ka tloaelo li fumaneha ha u kopa

5. Li-chamfer tse ngata tsa makenete tse ratoang ke bareki le mefuta e meng ea rona e amoheloang e le moralo o tloaelehileng kapa boholo indastering ea konkreite ea precast.

| Nomoro ea Karolo | A | B | C | Bolelele | Bolelele ba Magnet | Mofuta oa Lehlakore la Magnetized | Mocheso o Moholo oa ho sebetsa | |

| mm | mm | mm | mm | °C | °F | |||

| HM-ST-10A | 10 | 10 | 14 | 3000 | 50% kapa 100% | Motho a le mong | 80 | 176 |

| HM-ST-10B | 10 | 10 | 14 | 3000 | 50% kapa 100% | Habedi | 80 | 176 |

| HM-ST-10C | 10 | 10 | 14 | 3000 | 50% kapa 100% | Motho a le mong | 80 | 176 |

| HM-ST-15A | 15 | 15 | 21 | 3000 | 50% kapa 100% | Motho a le mong | 80 | 176 |

| HM-ST-15B | 15 | 15 | 21 | 3000 | 50% kapa 100% | Habedi | 80 | 176 |

| HM-ST-15C | 15 | 15 | 21 | 3000 | 50% kapa 100% | Motho a le mong | 80 | 176 |

| HM-ST-20A | 20 | 20 | 28 | 3000 | 50% kapa 100% | Motho a le mong | 80 | 176 |

| HM-ST-20B | 20 | 20 | 28 | 3000 | 50% kapa 100% | Habedi | 80 | 176 |

| HM-ST-20C | 20 | 20 | 28 | 3000 | 50% kapa 100% | Motho a le mong | 80 | 176 |

| HM-ST-25A | 25 | 25 | 35 | 3000 | 50% kapa 100% | Motho a le mong | 80 | 176 |

| HM-ST-25B | 25 | 25 | 35 | 3000 | 50% kapa 100% | Habedi | 80 | 176 |

1. Beha matla a makenete holim'a liforomo ka bonolo e le ho qoba limakete tse sentsoeng ke ho hohela ka tšohanyetso.

2. Limanete tsa Neodymium tse kentsoeng li tlameha ho bolokoa li hloekile. Qoba grout e koahelang limakete e le ho boloka matla a khoheli.

3. Ka mor’a hore se sebelisoe, se lokela ho bolokoa se hloekile ’me se tlotsoe ka oli e le hore se sireletsehe hore se se ke sa bola.

4. Mocheso o moholo oa ho sebetsa kapa oa polokelo o tlameha ho ba ka tlase ho 80℃. Mocheso o phahameng o ka etsa hore matla a khoheli a fokotsehe kapa a lahleheloe ke matla a khoheli ka ho felletseng.

5. Leha matla a khoheli a matla a khoheli a tšepe ea kgutlotharo a le tlase haholo ho feta makenete a koalang, a ntse a le matla ka ho lekana ho baka likotsi ho basebetsi ka ho pinching on impact. Ho roala liatlana ho sireletsa matsoho a motho ho khothaletsoa haholo. Ka kopo e behelle hole le lisebelisoa tsa elektroniki le litšepe tse sa hlokahaleng tsa ferromagnetic. Tlhokomeliso e khethehileng e lokela ho sebelisoa haeba motho a roetse mochine o otlang pelo, hobane matla a khoheli a matla a ka senya lisebelisoa tsa elektroniki tse ka har'a li-pacemaker.