1. Boitsebiso:Neodymium makeneteka boleng bo phahameng ba tshebetso le kereiti + Low carbon tšepe

2. Phekolo ea bokaholimo: Zinc, Ni+Cu+Ni, kapa epoxy bakeng sa Neodymium magnet + Zinc, pente kapa theknoloji e 'ngoe e hlokahalang bakeng sa mokotla oa tšepe.

3. Sephutheloana: se kenngoa ka har'a mabokose a masenke ebe mabokose a phuthetsoe ka phaleteng ea lehong kapa khese. Karolo e le 'ngoe, tse peli, tse tharo kapa tse ling tse ipapisitseng le boholo ka lebokose la masenke

4. Lever e phahamisang: Ho phahamisa lever mahala ha odara palo ea makenete e koalang e le kholo 'me ho bonolo ho e tsamaisa hammoho.

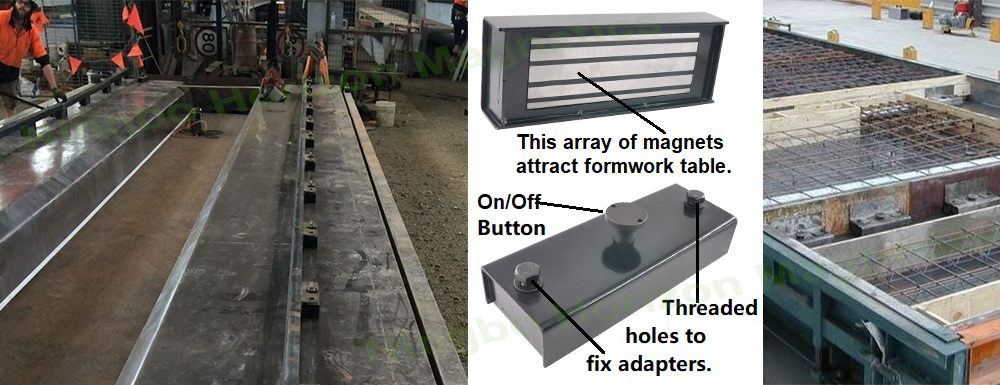

1. Limela tsa precast tse nang le tsamaiso ea tlhahiso e emeng ho hlahisa likarolo tsa konkreite, tse kang li-slabs kapa marako a mabeli

2. Lifeme tsa precast ho hlahisa menyetla e rarahaneng kapa e nyane, joalo ka mamati kapa lifensetere tse hlokang limatlase tse ngata tse koalang ho tiisa liforomo.

3. Likhamphani tsa Precast li hlahisa libopeho tse ikhethileng tsa likarolo tsa PC joalo ka radius, tse hlokang limatlase tse nyane tse koalang ho fapana le sistimi e telele e koalang ho hlahisa sebopeho.

4. Likhamphani life kapa life ntle le indasteri ea precast tse nahanang hore makenete e koalang e ka fihlela tlhoko ea bona mabapi le matla a holimo le ts'ebetso e bonolo.

1. Ho na le mefuta e mengata e nang le hoo e batlang e le lisebelisoa tsohle tsa liforomo, mohlala, lehong, tšepe kapa aluminium

2. Same makenete ho kopana le merero e fapaneng ka fastening formworks

3. Boholo bo eketsehileng le matla ho tloha ho 450 Kg ho isa ho 3100 Kg ho fihlela litlhoko tsa hau tse fapaneng.

4. Boholo bo kopaneng, bo bobebe ebile bo bonolo ho sebetsa

5. Boemo bo bonolo le bo nepahetseng

6. Qoba tjheseletsa kapa bolting ho tafole formwork kahoo ho boloka bokaholimo ho qetela

7. Likoti tse peli tse nang le khoele li kopantsoe ho ikamahanya le sebopeho

Tobetsa konopo e ka fetohang ka holim'a casing ea tšepe ho bulela matla a khoheli ho tiisa sebopeho ho tafole ea tšepe ka thata. Sebelisa lere la ho phahamisa ho hula konopo ho tima matla a khoheli ho sisinyeha le ho beha limakete tse koalang ebe o lokisa liforomo. Ka nako e 'ngoe, sebelisa masoba a mabeli a kopantsoeng ka holim'a makenete a koalang ho hokela li-adapter tse fapaneng, e le ho fihlela tlhokahalo e sa lekanyetsoang ea kopo.

1. Matla a tlholisano a ke keng a lekanngoa karolong ea bohlokoa ka ho fetisisa, Neodymium magnet, hobane Horizon Magnetics e tsoa ho tloha le ho ntse ho le teng.Ho etsoa ha makenete ea Neodymium

2. Ho itšepa ka boleng le ho amohela lipehelo tsa tefo joalo ka 100% T/T ka mor'a hore bareki ba fumane limatlase tsa rona tse koalang.

3. Phepelo e felletseng ea makenete a konkreite a precast joalo ka li-chamfer tsa makenete,kenya makenete, le bokhoni ba ho etsa machining ka tlung ho hlahisa lihlahisoa tse entsoeng ka maiketsetso ho kopana le theko ea bareki hang-hang.

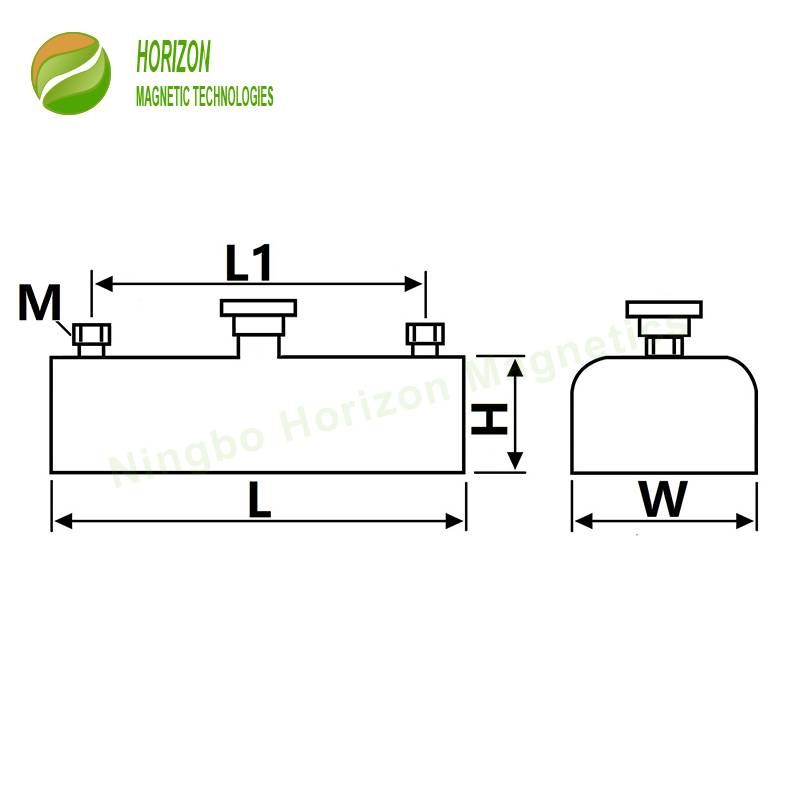

| Nomoro ea Karolo | L | L 1 | H | M | W | Matlafatsa | Mocheso o Moholo oa ho sebetsa | ||

| mm | mm | mm | mm | mm | kg | lbs | °C | °F | |

| HM-MF-0900 | 280 | 230 | 60 | 12 | 70 | 900 | 1985 | 80 | 176 |

| HM-MF-1600 | 270 | 218 | 60 | 16 | 120 | 1600 | 3525 | 80 | 176 |

| HM-MF-2100 | 320 | 270 | 60 | 16 | 120 | 2100 | 4630 | 80 | 176 |

| HM-MF-2500 | 320 | 270 | 60 | 16 | 120 | 2500 | 5510 | 80 | 176 |

| HM-MF-3100 | 320 | 270 | 60 | 16 | 160 | 3100 | 6835 | 80 | 176 |

1. Karolo e ka hare ea makenete ea Neodymium e tlameha ho bolokoa e hloekile. Qoba konkreite ho kena ka har'a makenete e koalang e le ho netefatsa hore matla a lekantsoeng a sala le konopo e fetohang e sebetsa ka mokhoa o bonolo.

2. Ka mor’a ho sebelisoa, e lokela ho bolokoa e hloekile ’me e tlotsoe ka oli e le hore e sireletsehe hore e se ke ea bola.

3. Mocheso o moholo oa ho sebetsa kapa oa polokelo o tlameha ho ba ka tlase ho 80℃. Mocheso o phahameng o ka etsa hore makenete o koalang o fokotse kapa o lahleheloe ke matla a khoheli ka botlalo.

4. Leha ho batla ho se na matla a khoheli a utluoang ka ntle ho sekoahelo sa tšepe sa makenete e koalang, matla a khoheli a lehlakoreng le kentsoeng a matla haholo. Ka kopo e behelle hole le lisebelisoa tsa elektroniki le litšepe tse sa hlokahaleng tsa ferromagnetic. Tlhokomeliso e khethehileng e lokela ho sebelisoa haeba motho a roetse mochine o otlang pelo, hobane matla a khoheli a matla a ka senya lisebelisoa tsa elektroniki tse ka har'a li-pacemaker.